“For some farmers, the word ‘benchmarking’ conjures up a dry and tedious process they’d rather not undertake, but it can be invaluable,” says Will Gemmill, head of farming at Strutt & Parker. “So we have come up with a set of simple management Key Performance Indicators (KPIs) that growers should be able to calculate without needing to delve into the details of their accounts.

“The figures, which are based on data we have captured from more than 145 farms, ranging from 100ha to 2500ha, will give an indication of how your farm compares in terms of labour and machinery costs and capacity. This can highlight areas where costs savings might be found and where it might be beneficial to dig deeper into the financials.

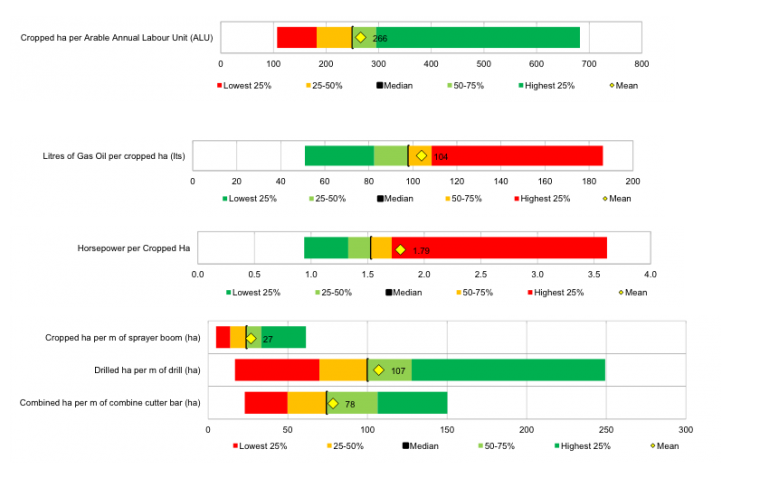

The six KPIs are as follows:

- Cropped hectares per arable labour unit

- Litres of gas oil per cropped hectare

- Horsepower per cropped hectare

- Drilled hectares per metre of drill

- Cropped hectares per metre of sprayer boom

- Combined hectares per metre of combine

The chart below indicates how other farm businesses are performing on these measurements with the mean (average) value highlighted by the yellow diamond.

Mr Gemmill said farming businesses needed to be as fit as possible to cope with the reduction or even loss of direct support payments, currently worth more than £200/ha, so the need to cut costs and improve efficiency was a pressing reality.

Strutt & Parker has recently completed a detailed benchmarking exercise for the AHDB Monitor Farms in England and Scotland.

It involved undertaking costs reviews of the labour and machinery used on the Monitor Farms to a level of detail which has not previously been done within generic farm benchmarking.

To help arable farmers review their current business operations, Strutt & Parker is offering detailed Arable Crop Production Reviews.

“No two farms are the same, but by calculating their costs and considering the logistics of making a change to their strategy, growers can get some answers to some searching questions such as: Would hiring a machine be more economical for the hours it does, could a contractor do the same job at the same cost or could sharing a combine with a neighbour work logistically?” said Mr Gemmill.

Case study

For example, a recent arable crop production review carried out on a 400 ha farm in the East of England found that the operational costs of growing a hectare of wheat was £387/ha which was above the average and down to much higher establishment and depreciation costs.

The farm is now looking at only ploughing where necessary for agronomic reasons and reducing the number of tractors from three to two with a hire tractor for use at the peak six-week harvest period.

“A review may be the catalyst for people to consider whether a joint venture would be a better way forward or a continued approach to improve cost efficiencies. We are involved with a wide range of joint ventures from full collaboration to partial and full Contract Farming Agreements.

“Equally, it can also highlight how much of a saving could be made by changing the buying strategy on inputs. For example, looking at the price of three commonly-used chemicals applied during the 2017 harvest we found that growers who bought through our Best Buys service made a 30% saving compared with those paying a serviced price for product.

“It is interesting to note that our research suggests that there is no obvious relationship between the size of the farm and its costs. We have also seen that farms with the lowest costs do not necessarily have less horsepower available – just cheaper horsepower. This might be achieved by operating over a large area, but can also be the result of where machines are being kept for longer and residual values kept high through regular maintenance.”

Strutt & Parker’s arable crop production reviews include:

- Crop yields – A comparison of historic performance against farms which are similar in their soil type, geographic location and management operation.

- Inputs – A review of the seed, fertiliser and spray programmes applied, during the 2017 Harvest year, along with individual price benchmarking for selected spray products against the Strutt & Parker buying group.

- vLabour – A review of the labour profile of the business and how it compares with others in terms of both training/skill level and cost per hectare (including benefits such as accommodation).

- Power and machinery – A detailed breakdown of power and machinery costs including an accurate cost review for each machine and actual costs for each operation (ie ploughing, drilling and combining) to create an operational cost for each crop type.

- Recommendations – A personalised summary of recommendations which can be used to review overall profitability and advice on the practical steps that can be taken to make a positive change on farm.