This month Nigel Akehurst visits Burnt House Farm in the village of Waldron, near Horam, East Sussex, to meet entrepreneur and third generation dairy farmer Joe Delves. He and his family own and operate a successful dairy farming enterprise across four sites in East and West Sussex. They also run The Traditional Cheese Dairy, a small cheese-making business they acquired just over two years ago.

Arriving at the farm, I drive past a large silage clamp where a group of dairy cows is congregated outside enjoying the unseasonably warm weather. I park outside a modern green building with the branding of The Traditional Cheese Dairy proudly emblazoned in white.

As I head towards the yard I meet Joe Delves, the third generation of his family to farm at Burnt House Farm. After a quick chat he suggests a tour of the cheese dairy. We head inside and I get changed into a pair of clean white boots and put on a blue coat.

Cheese dairy tour

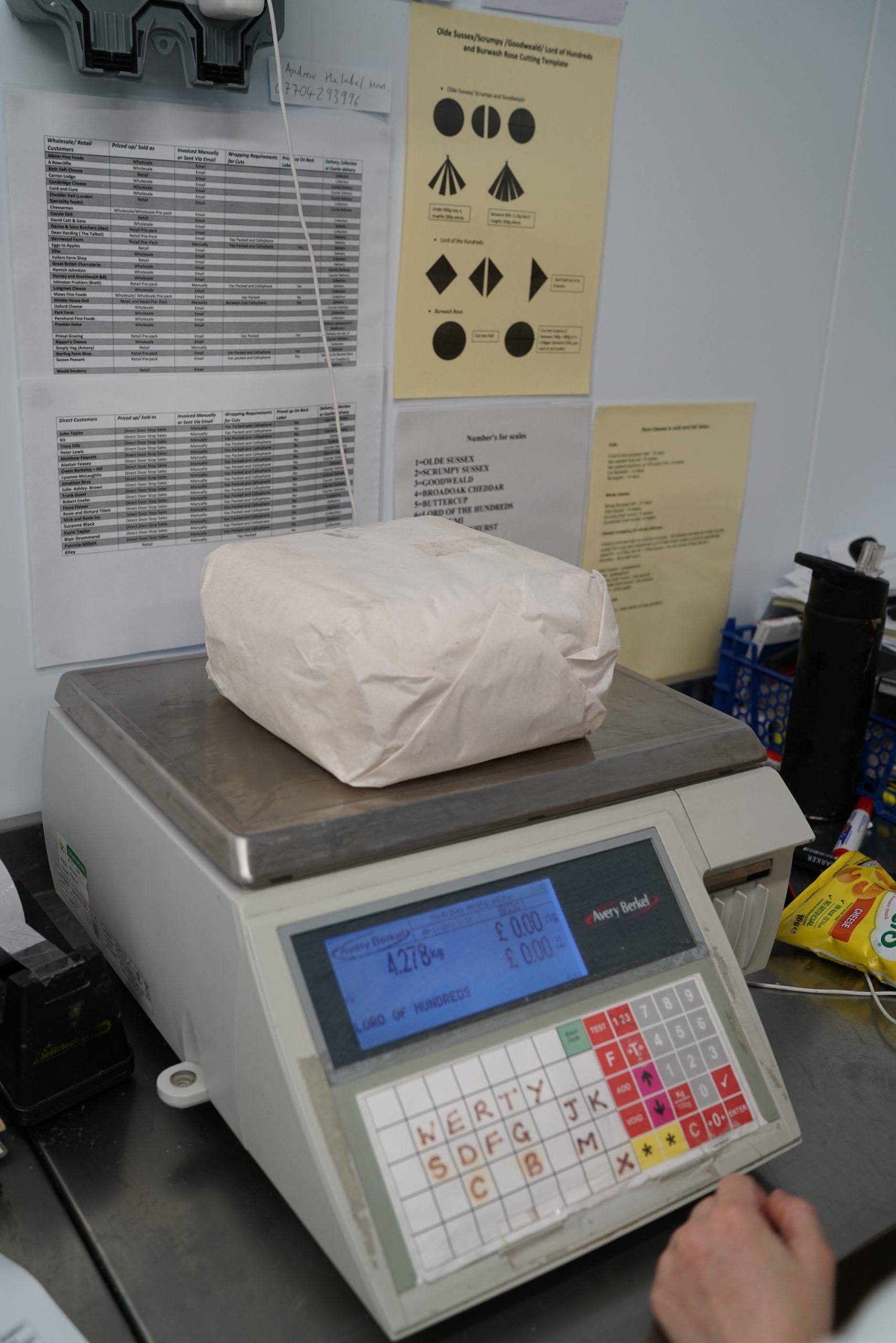

After giving my hands a good scrub we enter the cheese dairy. Everything is white and spotlessly clean. In the first room Joe introduces me to his wife Becky and Rowena Topping, a Plumpton college student, who are busy preparing cheese orders ready to be dispatched. Moving on to the make room, I meet head cheese-maker Ben Cottingham (who also happens to be Joe’s cousin).

Ben is pasteurising milk ready to make a fresh batch of their best-selling Burwash Rose, a delicious soft cheese (which I later get to try). Joe points out two metal pipes used to transport the milk directly from the bulk tank next door. This essential bit of infrastructure allows them to preserve the important milk fats (which can be disrupted when you pump the milk from a tanker, he explained).

“I always dreamed of adding value to our milk but it wasn’t until early 2020 that the opportunity arose to buy a local cheese-making business based in Stonegate,” he said.

The Dyball family had put their business, The Traditional Cheese Dairy, up for sale. It was “perfect timing,” said Joe, and after a short period of negotiation with the family they agreed on a figure.

The deal included five cheese recipes (Burwash Rose, Olde Sussex, Goodweald Smoked, Lord of Hundreds and Scrumpy Sussex), all the business’ existing stock, its customer base and its equipment.

Crucially it also included an intensive crash course in cheese making. Joe persuaded his father Andy (then 68) to come out of retirement and he spent the month of July learning how to make the five cheeses from scratch.

Everything went well and Andy took to his new role as head cheesemaker, with other members of the family pitching in. They continued to make and sell cheeses from the Stonegate premises for several months but then received a letter notifying them that the landlord wouldn’t be renewing their lease.

With nowhere else to go, Joe managed to negotiate a six month extension and they set about applying for planning permission to build their own facility on the footprint of an old pole barn on the home farm.

Approval was granted in less than a month, helped by local people writing letters of support, he said. Work started in early 2021, with Joe and some of his team carrying out the groundwork ready for the building supplier, Sussex Steel Construction, to put it up. The empty shell was up by

1 April, ready for the installation of the cheese rooms by contractor Lee Whiting from Octego Ltd.

It took less than three months to complete the installation ready for the cheese-making kit to be moved. Joe and the team dismantled and moved all the equipment “farmer style” onto a low loader at the weekend so as not to block access.

Remarkably, throughout the process they only stopped selling cheese for about two weeks (and stopped making it for about a month). Once up and running at the home farm, they started to use their own milk (though still purchase some in from Steve Reynolds to fill the seasonal supply trough), which presented some new challenges. They discovered that their milk had a greater variation in milk solids, resulting in some dud batches of cheese, explained Joe.

They have since been able to tweak the recipes to get back on track, and cheese sales went from strength to strength during Covid-19. Andy continued in post until this spring, when he decided to step down to let Ben take the reins.

Over half of their cheeses are now sold through the Brighton based wholesaler The Cheese Man. They also retail their cheeses via their website for postal delivery or for collection from the dairy Monday to Friday: www.thetraditionalcheesedairy.co.uk

They have also just invested in a cheese vending machine, said Joe. This is expected to arrive shortly and will allow customers to buy cheeses from the farm gate 24/7.

Completing our tour of the dairy, Joe showed me their maturations rooms. Each cheese has its own temperature-controlled room where the cheese wheels are stacked on wooden shelves and turned regularly.

Background

We head over to the farmhouse (where Andy and Liz live) for a chat. Joe’s grandparents Ronald and Joyce Delves started milking cows on the farm in 1962, originally renting the land before being given the opportunity to buy it in 1972. After agricultural college, Andy returned to the family farm to help his father. Over the years they specialised in high producing Holsteins and increased the size of the herd to more than 100 cows.

Growing up on the farm, Joe left school and went to work for a local sheep farmer. After a couple of years he decided he didn’t like sheep and went into construction work. Initially laying tarmac, he ended up starting a small building business with a friend. “It was good fun and we learned a lot,” he said.

During this time Andy took up the offer of full-time job running an evangelical church (now called Kings Church) in Heathfield that he had helped set up. The role came with a house, so he and Liz moved out of the farmhouse and employed a herdsman to live on site and milk the cows.

“None of us was here. It broke this cultural mentality that it has to be someone in the family that milks the cows,” said Joe.

Then, in 2005, the herdsman left and Joe decided to have a go at dairy farming. He and his wife Becky moved into the farmhouse. “I hadn’t really run a farm before and hadn’t milked cows full-time,” he said.

His dad was around but tried not to get too involved and left him and granddad to work out their differences, both eventually becoming good friends.

The first few years were tough, as they were still in the old buildings and everything was hard work, he explained. Like a lot of people at the time they thought about stopping completely and explored going into industrial units.

Tesco cost of production contract and investing in new farm infrastructure

In 2007 Joe rang Arla to say they were thinking about giving up. Arla was supportive and asked them to hold off for a couple of weeks, explaining that they would receive a letter in the post.

“We then received a letter saying we’d been selected as a Tesco’s farm and they would pay us on a cost of production basis. Overnight the milk price went from 16p to 21p,” he said.

By then they were debt free, but the farm infrastructure was outdated and in poor shape and production costs were too high. “It wasn’t efficient and the farm was miserable to operate,” he said.

Joe and Becky went to see their Barclays bank manager, who Joe described as “brilliant”, explaining: “She was keen to lend us some money, so we decided to bulldoze the existing buildings and start again.”

With planning permission granted for a modern cowshed, they started work in April and it was meant to be finished by July. Typically it was one of the wettest years on record and they didn’t get back in until December.

After that they bought some more cows in and started to make some money. “The accountants in Heathfield were a bit shocked at some of the numbers that started to come out,” Joe said.

Moving to seasonal calving, Nuffield Scholarship and dairy expansion

In 2010 Joe went out to New Zealand with a friend to visit some dairy farmers. It was a real eye opener and introduced him to the idea of seasonal calving. “Calving with the weather rather than stressing the system and trying to calve all year round” is how he describes it.

He was impressed with their business focus: “They only keep cows because they make money,” he pointed out.

It was an attitude that struck a chord, and on his return to the UK he decided to move to an autumn block calving system. It’s a system which works well in the South East, as the cows produce their peak milk in the winter off silage and then dry off for six weeks in the summer when the grass is at its worst.

He also changed the breeding from extreme Holstein to cross breeds using Jerseys: “We went back to how Grandad farmed,” he said.

Then in 2012 Joe won a Nuffield Scholarship which resulted in him producing How to succeed in dairy farming. It was a real game changer, he said, and he spent several months in 2013 visiting different farms around the world before writing his report.

“That’s when I wanted to challenge us a bit more and so I decided to take on another farm,” he said. In 2014 an opportunity arose to take on an organic dairy farm in Petworth, West Sussex.

“It was organic and it helped de-risk us. Both prices are volatile but organic doesn’t bottom out like the conventional. If it bottoms too low then the supply stops. With the conventional price it keeps doing down. In 2016 we had a massive slash down but the organic price only came down a bit and then went nice and flat,” he explained.

Other than the cows, the most important part of the business is people, said Joe. They spent 2016 to 2019 getting the right staff in place and consolidating costs. Then, in May 2020, they entered into a contract farming agreement with Tom and John Randle on their two dairy farms in Fletching.

“They had got to the point where they wanted to stop dairy farming but were keen to carry on having cows on the farms, as they had been there for a long time,” explained Joe.

It’s an arrangement that has worked well for both parties and something they would be keen to do more of, he said. It’s very low risk for everyone and Joe sees collaboration as the best way to grow the business; they get what they need as well as allowing us to expand and farm more acres, he explained.

“As we’ve got bigger, we can buy things cheaper and do things more centrally and they get the advantage of that,” he added

Joe now employs 12 full-time staff and points out that he is the only one that has a connection to farming.

When recruiting, they post adverts on social media sites like Facebook and often prefer applicants with a clean slate, including many who have never seen a cow before.

“We don’t mind putting time into people, who are the backbone of the business (aside from the cows) at the end of the day,” he added.

Farm tour

Before leaving we head out onto the farm to meet a couple of the farm team; Ben Pike, the farm manager, and his assistant Emily Farrant. They showed me the cows, the majority of which were enjoying the fine weather in the outdoor silage clamp.

The cows looked well and I asked what their average milk yield was. “They average around 7,000 litres of milk a year,” replied Ben, adding that they are targeting 7,500 litres, with plans to breed a bit more size back into their cross-breed cows.

It’s all about finding the sweet spot, he said. After a couple of stressful years they decided to reduce their cow numbers on the farm and all of a sudden it just gets a bit easier and more enjoyable, he went on.

I asked if they were concerned about the rising costs. “Our costs are going up but we are still benefiting from existing stocks of fertiliser and fixed price electricity until next year,” replied Joe.

He thinks the next 12 months will show a truer reflection of costs and highlighted the incoming slurry regulations, which will mean more investment and may force more dairy farmers out of the industry.

What a lot of people don’t realise is that it’s a watershed moment for a lot of family farms, with an outgoing generation and no incoming generation to replace them, he said.

Succession, the importance of discussion groups and a good accountant

For many family farms, succession is a taboo subject, but Joe believes many of the best businesses are passed on sooner rather than later.

“A lot of the good farmers around here sadly had an early succession, due to their dad dying or something tragic happening. Ironically they are the ones that are now holding on to the farm, when they should have got out of the way years ago. They are now holding the businesses back, which I think is a real shame.”

Joe said being the boss can sometimes be lonely and said he found it useful to meet up with other entrepreneurs and business owners, often outside farming, to chat and share ideas.

He is also involved in a number of dairy discussion groups, which he has found useful and has helped him improve his business.

Moving to a larger agricultural accountants (Chavereys in Faversham) had also helped them grow, he said.

Future plans

Joe is passionate about people and cows and is focused on getting to 2047, which would be the 100-year anniversary of the farming business, and on giving the next generation the opportunity to take on a profitable sustainable business.

Farm facts

- 2,100 acres farmed

- Spilt across four farms (three conventional and one organic)

- 630 cows conventional

- 280 cows organic

- 5.7 million litres total sold to through Arla to Tesco and McDonald’s

- Autumn block calving

- Small cheese business

- 12 people employed full time, including in the cheese business

- Ben, head cheese maker

- Joe’s wife Becky

- Assistant Emily

- Joe and his farm manager Ben